What is a Damper Actuator and How Does it Work?

A Damper Actuator is a crucial component in many HVAC systems. It regulates airflow by adjusting the position of dampers in response to control signals. According to the U.S. Department of Energy, efficient airflow management can improve energy savings by up to 30%. This makes understanding damper actuators essential for optimizing system performance.

Despite their importance, many buildings still use outdated or improperly sized actuators. A study by ASHRAE revealed that nearly 25% of buildings have airflow issues. These problems often lead to increased energy costs and discomfort. Thus, evaluating the effectiveness of a Damper Actuator can provide valuable insights.

Integrating modern damper actuators can address these challenges. They deliver precise control over airflow, enhancing energy efficiency and overall indoor air quality. Yet, it is vital to reflect on potential issues during installation and maintenance. Ensuring proper calibration and compatibility with existing systems is critical for achieving the desired outcomes.

What is a Damper Actuator?

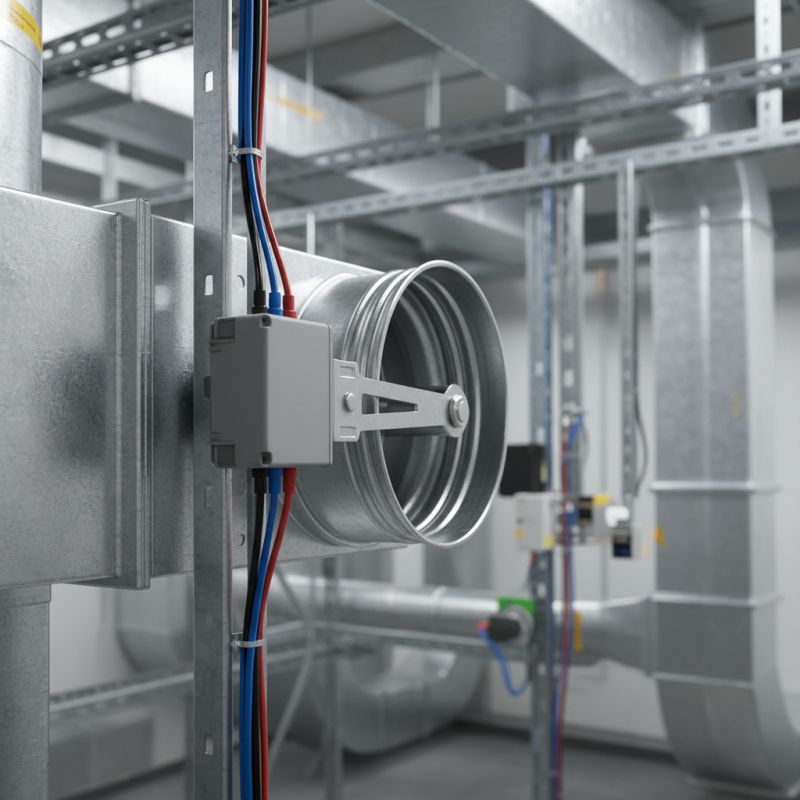

A damper actuator is a device used to control airflow in HVAC systems. It adjusts the position of dampers in ducts. These dampers regulate the volume of air entering or leaving various zones. A damper actuator operates using either electric or pneumatic means.

Understanding its function is crucial for efficient HVAC operation. For example, an electric actuator uses a motor to turn the damper blades. This movement can be either open or closed. Pneumatic actuators rely on air pressure, which can be less precise at times. The choice between the two can affect system performance.

Installation can present challenges. If the actuator is not calibrated correctly, airflow issues may arise. This can lead to discomfort and inefficiencies in a building. Regular maintenance checks are essential, but often overlooked. Ensuring proper functionality can prevent more significant problems in the future. A few simple adjustments may make a noticeable difference in comfort levels.

Types of Damper Actuators and Their Applications

Damper actuators play a vital role in controlling airflow in various systems. There are mainly two types: electric and pneumatic actuators. Electric actuators are preferred for their precision and ease of integration into automated systems. They often use feedback loops for accurate positioning. On the other hand, pneumatic actuators are known for their rapid response times. This makes them suitable for applications requiring immediate adjustments, such as in HVAC systems.

Recent reports indicate that the demand for damper actuators is expected to grow significantly. The global market for building automation systems, where these actuators are commonly employed, is projected to reach $100 billion by 2026. This growth is primarily driven by an increasing focus on energy efficiency in buildings. However, challenges remain. Many systems still rely on outdated technologies, which can lead to inefficiencies. Upgrading to modern actuators requires investment and careful planning.

Applications for damper actuators extend beyond HVAC. They are essential in industrial processes and even automotive designs. Each application may require specific actuator features. For instance, heat-resistant materials are critical in high-temperature environments. Yet, the compatibility of actuators with existing systems often raises questions. Addressing these compatibility issues is crucial for successful implementation in various sectors.

Types of Damper Actuators and Their Applications

How Does a Damper Actuator Function?

A damper actuator is a crucial component in HVAC systems. It controls the airflow by adjusting damper blades. These blades regulate air volumes in ducts. Understanding how a damper actuator functions is essential for effective climate control.

When the actuator receives a signal, it moves the damper blades. This movement depends on the actuator's type—electric or pneumatic. Electric actuators are popular for their precision. Data shows that electric actuators can improve airflow efficiency by 20%. This efficiency leads to energy savings, making HVAC systems more sustainable. However, improper calibration can lead to airflow issues.

One common challenge is actuator responsiveness. If the actuator is slow, it may not react to system changes quickly. This can result in temperature inconsistencies. Maintenance reports indicate that regular inspections are necessary to ensure optimal performance. Some installations lack this routine care, leading to reduced reliability. Understanding these nuances can help in using damper actuators more effectively.

Key Components of a Damper Actuator

A damper actuator plays a crucial role in controlling airflow in HVAC systems. It regulates the position of dampers, devices that control air passage. The main components include the actuator motor, gear assembly, and control system. Each part has its own function, working together to achieve precise movement.

The actuator motor provides the necessary torque to move the damper. It converts electrical energy into mechanical motion. This action ensures that the damper opens or closes as needed. The gear assembly amplifies the motor's output. It translates the motor's rotation into linear motion, effectively controlling the damper's position.

Lastly, the control system sends signals to the actuator. This can be a simple on/off switch or a more complex control panel. It’s important to note that calibration is essential. If the actuator does not align properly, airflow can become inefficient. Regular maintenance is needed to ensure both the actuator and the damper function correctly. Without proper care, the system can face unexpected failures.

What is a Damper Actuator and How Does it Work? - Key Components of a Damper Actuator

| Component | Description | Function |

|---|---|---|

| Motor | Electromechanical device that provides the driving force. | Converts electrical energy into mechanical motion. |

| Gearbox | Mechanism that transmits power from the motor. | Adjusts the speed and torque of the motor output. |

| Linkage | Connects the actuator to the damper blade. | Translates the motor motion to the damper movement. |

| Control System | Electronics that monitor and manage actuator operations. | Ensures proper positioning and response to signals. |

| Sensors | Devices that detect positional feedback. | Provides data to the control system for precise adjustments. |

Benefits of Using Damper Actuators in HVAC Systems

Damper actuators play a critical role in HVAC systems. They regulate airflow efficiently, ensuring comfort in various environments. When paired with dampers, these actuators control the opening and closing of air passages. This functionality leads to better temperature regulation.

One major benefit of using damper actuators is energy efficiency. They help reduce energy consumption by optimizing airflow. This results in lower utility bills over time. Furthermore, they enhance indoor air quality by ensuring proper ventilation. However, installation can be tricky. If not placed correctly, performance may suffer, leading to wasted energy.

Incorporating damper actuators can also improve system response times. They allow HVAC systems to react to temperature changes swiftly. This creates a more comfortable living or working space. Yet, maintenance is essential. Regular checks can prevent malfunctions and prolong actuator life. If ignored, systems may fail to perform optimally.