How to Choose the Right Rubber Pump Impeller for Your Needs?

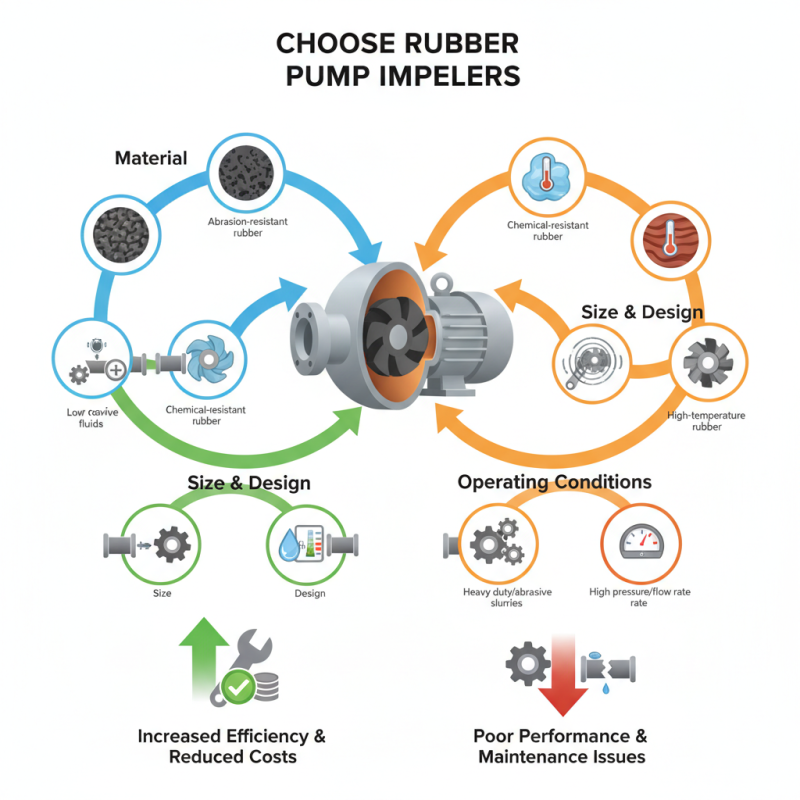

Choosing the right Rubber Pump Impeller is crucial for efficiency. It affects performance and longevity. Selecting the wrong impeller can lead to inefficiencies and increased costs.

Factors like material, size, and design impact your choice. Rubber Pump Impellers are popular for their durability and flexibility. They work well in various applications, especially in corrosive environments. Understanding your specific needs is essential to avoid mistakes.

Consider your pump's operating conditions. The right Rubber Pump Impeller can enhance flow rates and reduce maintenance. However, neglecting these details might result in poor performance. Taking the time to evaluate your options can save you time and resources in the long run.

Understanding the Basics of Rubber Pump Impellers

Rubber pump impellers are crucial components in fluid handling systems. They control flow rates and ensure efficiency. Understanding their material properties is essential for effective selection. Rubber impellers provide flexibility and resilience. They resist wear and handle varying operating conditions well.

A recent industry report indicates that rubber impellers can improve pump efficiency by up to 30%. This statistic highlights their importance in optimizing processes. However, choosing the right type is not straightforward. Factors such as fluid viscosity, temperature, and chemical compatibility must be considered. Some users overlook the impact of these factors, leading to premature wear or failure.

In applications involving harsh chemicals, standard rubber might degrade quickly. Users need to evaluate specific requirements. Testing in real conditions can be beneficial. Regular maintenance and monitoring are vital. Neglecting these aspects can cause significant downtime. Balancing cost and performance is often tricky, but essential for long-term success.

Identifying the Specific Requirements for Your Application

When selecting a rubber pump impeller, it’s crucial to identify the specific requirements for your application. Consider the fluid type you will be pumping. Different fluids have varying viscosities and chemical properties. This impacts the impeller material you choose. Rubber impellers offer resistance to corrosion, but some fluids may need specialized compounds.

Keep in mind the flow rate you require. Too high a flow rate might cause cavitation. Too low can lead to efficiency losses. Finding the right balance is key. Understand the operating conditions, including pressure and temperature ranges. Ensure the impeller can handle these demands without degradation.

Tip: Always consult with a technical expert. Their insights can be invaluable. They might point out flaws in your initial choice.

Don’t forget to consider the size and fit of the impeller. Ill-fitting components can lead to inefficiencies. Over time, this can affect the pump's overall performance. Assess other system components too. Any mismatch in size or material can lead to operational issues.

Another Tip: Regularly review your application requirements. They can change over time, and adjustments may be necessary. Being proactive can save costs and time in the long run.

Evaluating Material Compatibility and Durability Factors

When selecting a rubber pump impeller, material compatibility is crucial. Different fluids react differently with rubber compounds. For instance, a 2021 industry report indicated that 30% of pump failures stemmed from material incompatibility. Understanding the fluid's chemical properties can prevent costly downtime.

Durability factors are equally important. Rubber impellers experience wear due to friction and environmental conditions. Research shows that natural rubber impellers typically last about 1,000 hours in high-stress situations. In contrast, synthetic alternatives can extend the lifespan to 2,500 hours. Choosing the right material directly impacts operational efficiency.

Consider also the temperature range. Certain rubbers can only function effectively within a specific temperature span. Exceeding this can lead to deformation or reduced performance. There remains a tendency within the industry to overlook these criteria, often leading companies to question their choices after failures occur. It's essential to analyze not just the initial purchase cost but the long-term performance.

Considering Pump Performance Characteristics and Efficiency

Choosing the right rubber pump impeller involves understanding pump performance characteristics and efficiency. Impellers significantly influence how well a pump operates. A well-designed impeller can enhance performance and reduce energy costs. A recent industry report shows that optimizing impeller design can improve pump efficiency by 10-20%.

Consider flow rate and head pressure when selecting an impeller. A mismatch might lead to cavitation, which causes damage. You can measure these factors accurately with the right tools. Many users overlook these measurements, leading to poor performance and increased wear. In some cases, users rely solely on recommendations rather than analyzing their specific needs. This approach can result in inefficiency.

Rubber impellers offer flexibility in applications, especially in corrosive environments. However, their performance can vary widely based on material composition. Some rubbers degrade under certain conditions, affecting efficiency and lifespan. Research shows that using high-grade synthetic rubber can enhance performance, but many fail to upgrade. Analyzing your pump's operating conditions is crucial for selecting the appropriate rubber type.

How to Choose the Right Rubber Pump Impeller for Your Needs?

| Impeller Type | Material | Efficiency (%) | Head (m) | Flow Rate (m³/h) | Application |

|---|---|---|---|---|---|

| Open Impeller | Natural Rubber | 85 | 15 | 200 | Slurry Handling |

| Closed Impeller | EPDM Rubber | 90 | 20 | 150 | Clean Water |

| Semi-Open Impeller | Nitrile Rubber | 88 | 18 | 180 | Wastewater |

| Vortex Impeller | SBR Rubber | 80 | 12 | 220 | Granular Solids |

Making an Informed Decision: Comparing Design Options and Costs

Choosing the right rubber pump impeller is not easy. It requires careful consideration of design options and costs. You'll find a wide range of impeller shapes and sizes. Each design serves a different purpose, impacting efficiency.

Cost is a crucial factor. Cheaper options may save you money upfront. However, they might not last long. You may end up spending more on replacements. More expensive designs often ensure better performance. Yet, they need a proper assessment of your specific requirements.

Don’t overlook your system's needs. Think about the type of liquid you'll be pumping. Consider viscosity and temperature. A mismatched impeller could lead to failures. Reflect on your operational environment as well. It all affects how well the impeller performs. Making an informed decision is vital; it could save you time and resources in the long run.